What is glTF? A Complete Guide for 2025

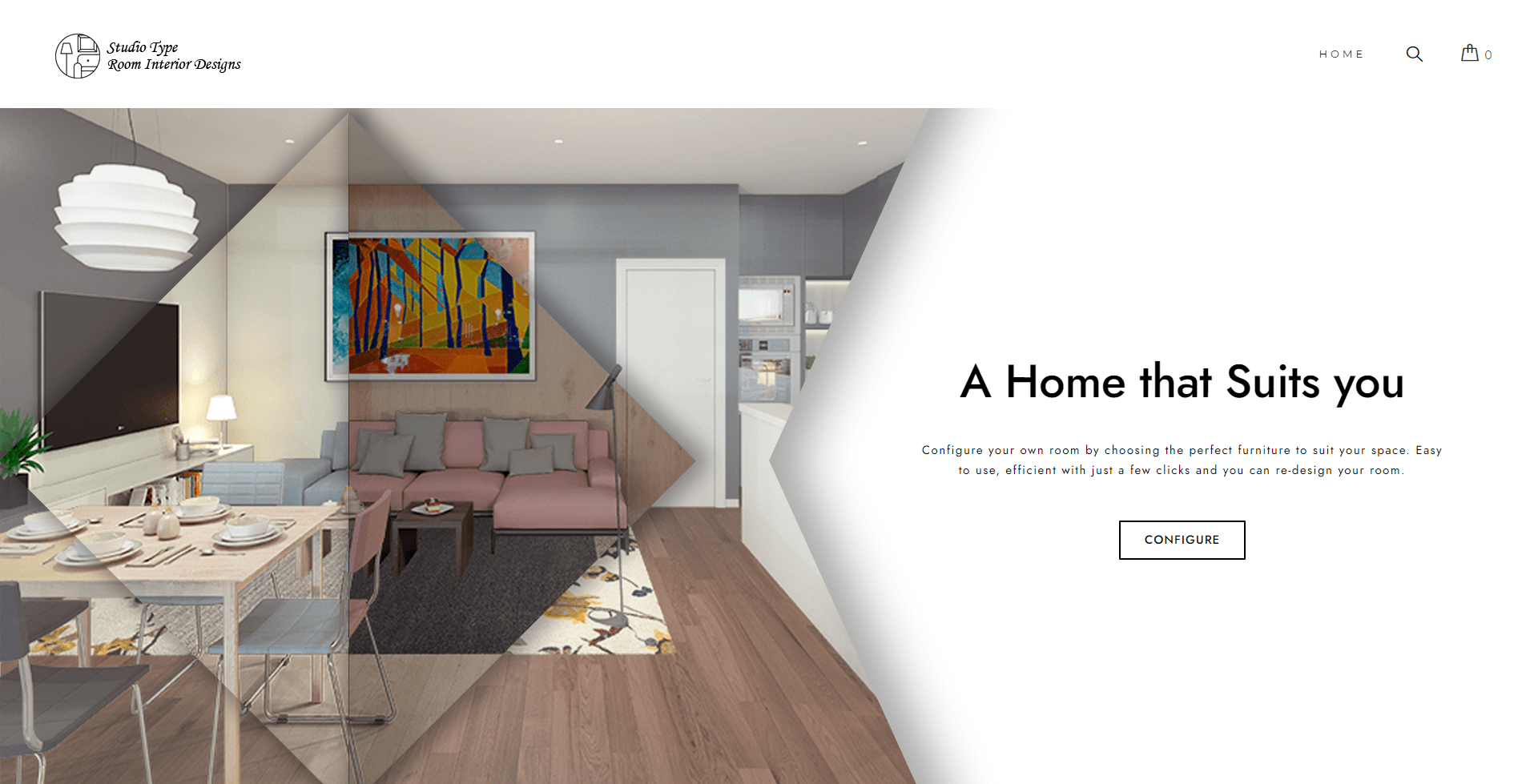

As 3D content becomes a bigger part of how we shop, design, and interact online, the need for smooth, fast, and realistic visuals is growing fast. Businesses and creators alike are looking for smarter ways to bring their 3D ideas to life—and that’s where glTF (GL Transmission Format) comes in. It’s quickly becoming the go-to […]